WELCOME TO YANYUETECH

Hot products

About Us

Shenzhen Yanyue Technology Co.,Ltd. was established in 2006, is a national high-tech enterprise specializing in the R&D, production and sales of Industrial Personal Computer, industrial computers, embedded intelligent boards and other products. With the company's strong strength, and many well-known IT enterprises at home and abroad to establish a good relationship of cooperation, to provide customers with all kinds of Industrial Personal Computer products and services....

-

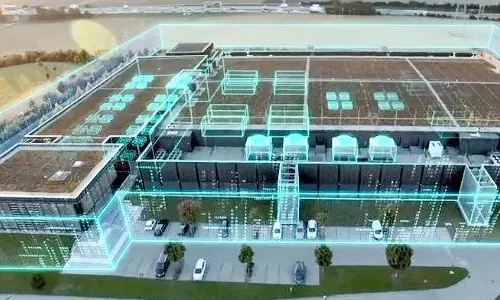

Industrial Automation

-

Smart Transportation

-

Artificial Intelligence

-

Warehouse Logistics

-

Chemical and Pharmaceutical

-

Information Security

News & Bolg

View More +The International Electrotechnical Commission Designates ISA

The International Society of Automation (ISA) and the ISA Global Cybersecurity Alliance (ISAGCA) are proud to announce that the International Electrotechnical Commission (IEC) has officially designated the IEC/ISA 62443...

New ABB Study On Industrial Transformation Unveils Critical

Billions of better decisions” highlights the role of Industrial IoT solutions in reaching sustainability goals while empowering the industrial workforce·International survey of 765 decision-makers reveals that while 96...

-

Unlocking Power and Flexibility: The Ultimate Guide to Rackm

Discover everything about rackmount PCs—from their design and advantages to their applications and future trends. Explore how these versatile machines are transforming modern computing environments....

View Details -

Unlocking the Power of the Box PC: The Future of Compact Com

Explore the versatile world of Box PCs, their innovative features, applications across industries, and why they’re transforming the landscape of compact yet powerful computing solutions....

View Details -

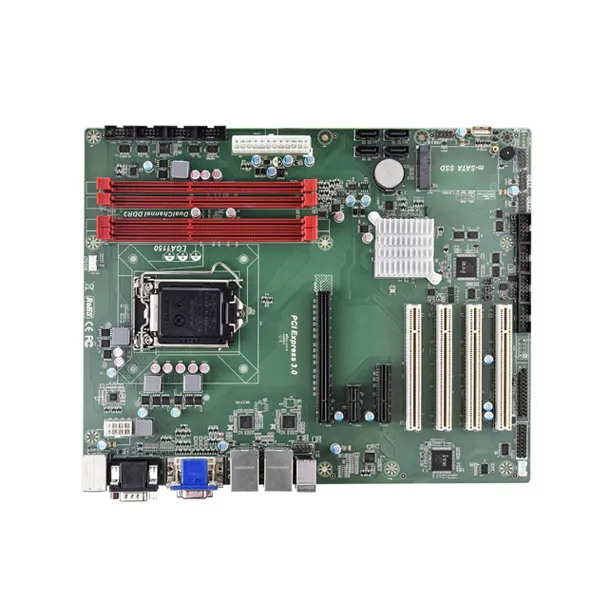

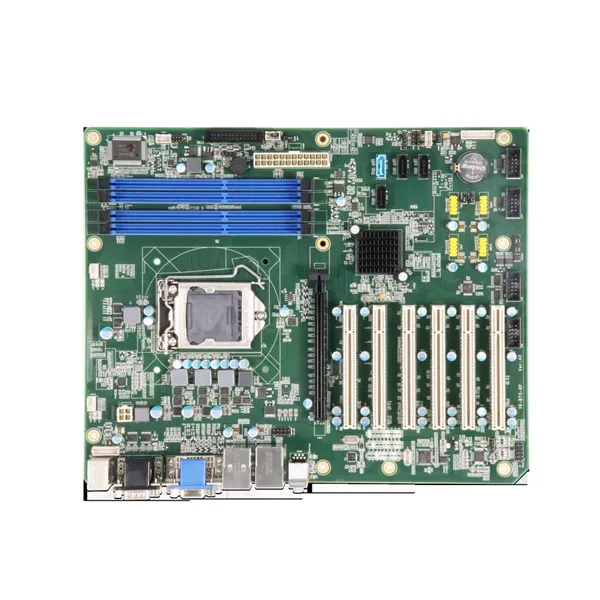

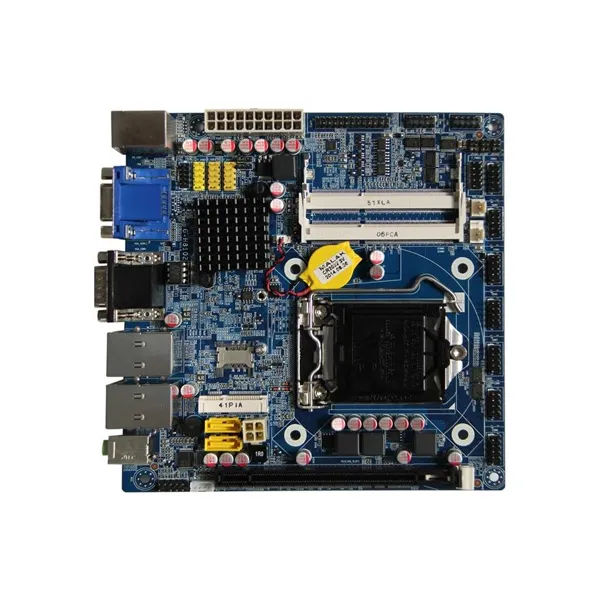

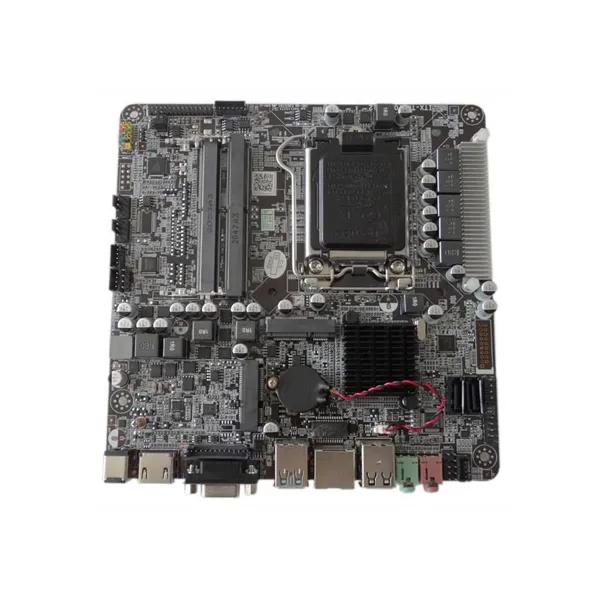

Industrial Motherboard: The Quiet Backbone of Modern Manufac

A soft, immersive look at how industrial motherboards power automation, robotics, and edge computing—from rugged design to long-term reliability—and why they matter on the factory floor and beyond....

View Details

One more of us, you have one more choice

Customized process

-

1

Manufacturing experience

Professional industrial computer products,True source manufacturer, professional team checks layer by layer

-

2

Strict quality inspection

Accurate sample preparation before production, to ensure the accuracy of dimensional data Good workmanship, good quality.

-

3

Products widely used

To provide our customers with better and more practical products.

-

4

After-sales service system

24-hour online customer service at any time to respond, so that you worry!